Before getting into wireless temperature sensors, we need to understand what a general temperature sensor does. A temperature sensor is a device which is implemented for measuring temperature or heat generated in a particular surrounding. The wireless temperature sensor is one of the most commonly used sensor types in the current market. Temperature sensing is done either by direct contact between the sensing element and the object or remotely, i.e. without direct contact. Temperature sensors come in a lot of different variants and can be divided into two basic categories.

Contact Type sensors, as the name suggests operate on the basis of an actual physical contact with the object being sensed. They use conductivity to read and monitor temperature changes.

Non-Contact Type sensors use processes like convection and radiation to monitor temperature changes. In convection processes, the heated up element moves upwards while the cooler part settles down in the bottom. So using this property, these sensors detect liquids and gases that emit radiant energy with an increase in heat. Using radiation property, they detect the radiant energy being transmitted in the form of infrared waves from the object.

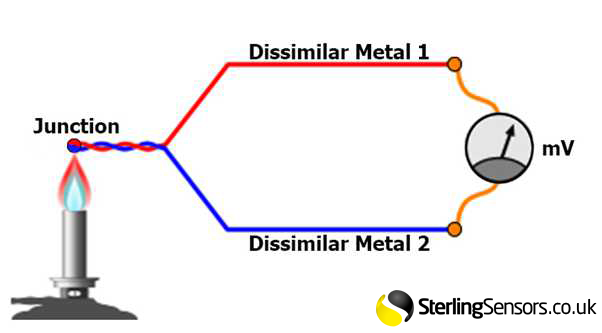

Thermocouples are thermoelectric sensors that consists of two junctions of different metals such as iron and constantan joined together. One of the two junctions is referred to as reference junction which remains at a constant temperature while the other junction has a variable temperature. When these two junctions are at different temperatures, a voltage is induced in between them. This voltage is used to measure the temperature. Thermocouple type sensors are simple, rugged and inexpensive. They have a wide temperature range (-200 C to 1700 C) and come in a variety of styles.

These sensors have a nonlinear response. The sensitivity is less. The output voltage is small, Least stable compared to other variants.

An image representation of how thermocouples work

Image taken from source

Type K (-270 C to 1260 C): Most commonly used. It is made from Nickel-Chromium/Nickel-Aluminium material. It is cheap, reliable, accurate and has wide temperature range.

Type J (-210 C to 760 C): This type is also common. It is made of Iron/Constantan material. It is similar to Type K in terms of expense and reliability. But it has shorter temperature range and has less lifespan at higher temperatures.

Type T (-270 C to 370 C): Type T has a good stability and is often used in low-temperature applications such as ultra low freezers. It is made of Copper/Constantan material.

Type E (-270 C to 870 C): Type E commands high accuracy and stronger signal reception compared to type K and J. It is made of Nickel-Chromium/Constantan.

Type N (-270 C to 392 C): Type N is made of Nicrosil/Nisil and is slightly expensive compared to type K and type J.

Type S (-50 to 1480 C): Type S has high accuracy and stability. It is made of Platinum Rhodium-10% and is used mostly in high-temperature applications like biotechnology or pharmaceutical industries.

Type R (-50 C to 1480 C): Type R is very similar to type S in terms of accuracy and stability. It is made of Platinum Rhodium-13% It is implemented in applications which deal with very high temperatures as it has more concentration of Platinum. It is also more expensive.

Type B (0 C to 1700 C): It is similar to Type S and Type R except that it has the highest concentration of platinum and is used in extremely high-temperature applications. It has the highest temperature limit among all the thermocouples listed above.

Graphical representation of thermocouple performance. Image taken from source

Image taken from source

As already mentioned above, thermocouples have two different metal alloys joined together at a measurement junction and we are going to use that to our advantage in order to build up a thermocouple-based temperature sensor. For this purpose, we use a K type thermocouple as it is inexpensive and has a good sensing range. Now the problem in interfacing a thermocouple with a measurement circuit is that the output voltage signal is very weak. To overcome this, we require a signal conditioning circuitry which amplifies the signal to a proper voltage output. We can use LM358 for this purpose which can increase the gain up to 250. This much is adequate for our purpose. But the problem doesn't end here. Opamp based signal conditioning is good up to an extent. To get precise and accurate temperature measurement, we require a 'cold-junction temperature correction circuit'. A thermocouple output voltage is the measurement of the temperature difference between hot end and cold end. But the actual hot end temperature is different. To solve this problem, we simply add the cold end temperature to it. MAX6675 is a module from Maxim that does the same job. It has a temperature sensor in it that detects the cold end temperature which is the same as the circuit board temperature on which the module is mounted. It simply adds the value and converts the output of thermocouple into a 12-bit resolution, SPI compatible signal which we feed to the Arduino.

RTD stands for Resistive Temperature Detectors. These are also known as precision temperature sensors. These are made of highly pure metals such as copper or platinum wound into a coil. The electrical resistance of these metals changes as a function of temperature. RTD has positive temperature coefficient or PTC which means that the resistance increases with increase in temperature.The output of this type is very linear and thus produces very accurate and precise results. The main drawback of these sensors is that they have very poor thermal sensitivity. This means that for a given change in temperature, the output change is very less.

This variant is quite stable with good linearity. A unit change in temperature would result in a unit change in voltage output across the entire temperature range of the sensor. Temperature range (-250 C to 650 C) Accuracy of this type is also high. The problem with this type is that the sensitivity is less. The output resistance is small. Has to be powered externally and gives out wrong data at times because of self-heating. RTD based sensors are made from platinum and are very costly.

This is how RTD sensors look like. Image taken from source

This variant of the temperature sensor is a special type of resistor which changes its resistance value when subjugated to heat. These sensors are very much fast when it comes to the response time and accuracy as compared to other variants like the thermostat. There are two types of thermistors:

Negative Temperature Coefficient (NTC)

Positive Temperature Coefficient (PTC)

In NTC type, the resistance value goes down with an increase in temperature.

In PTC type, the resistance value goes up when temperature value goes up.

This variant has fast operation tendency with high output and minimal lead resistance error. Temperature range (-40 C to 250 C).

The problems are that these have a very limited temperature range. Have to be powered externally. They are nonlinear. Very fragile and has a tendency to generate self-heating error.

Different types of NTC thermistors. Image taken from source

The thermostat acts like an electromechanical switch between two electrical contacts which either opens up or closes down depending on the temperature. It contains a bimetallic strip which consists of 2 different metals having different linear expansion rates, bonded together. Because of this, the metallic strip bends when subjected to different values of heat, disconnecting the flow of current. It is used extensively in hot water heating elements, boiler furnaces, vehicle radiators and hot water tanks.

The basic representation of how a thermostat works. Image taken from source

Two types of bimetallic strips are used :

On/Off or Snap-action type

Creeper-action type

Snap-action type disrupts the flow of current instantaneously at a preset temperature point. These are used in a variety of different household equipment like ovens, irons, domestic heating systems. The drawback of this type is that there is a hysteresis range, which means that it is not necessary that the contacts will open and close at the same exact temperature.It might close open at 30 and close at 40 one time. But the next time it will open at 33 and close at 38 or some value near that.

Infrared temperature sensors detect electromagnetic waves that are in the range of 700 nm to 14000 nm. These sensors focus mostly on infrared radiation emitted by the object. This sensor consists of photodetectors that convert infrared energy into an electrical signal. Since the infrared energy and the temperature of the object are proportional to each other, the electrical signal in turn generated provides an accurate reading. The infrared signals enter into the sensor element through a small window. This small window is made up of a special form of plastic that allows only a particular band of frequencies. It also protects the inner sensing element from dust, dirt, and moisture. This type of sensor is well suited for moveable objects where a contact is not possible. Also since this sensor doesn’t need any kind of contact, wear and tear problems are very less. Apart from being just a temperature sensor, it can also be used as motion detector by measuring fluctuations in temperature in the field of view. The problem with this sensor is that they tend to get confused with the background sources of infrared radiation. In order to overcome this problem, narrow the field of view of the sensor so that it is constrained entirely to the object being measured.

MLX90614 infrared sensor. Image taken from source

Example for Implementing infrared sensor: This sensor can be interfaced with an Arduino board by using I2C communication protocol. The sensor will work when it get +3.3V DC supply from the Arduino board. It should be connected as per the given diagram:

Image taken from source

Semiconductor sensors are based on ICs (integrated circuits) which offer high linearity and high accuracy over a wide operating temperature range(-55 C to +150 C). Since these are integrated circuits, they can contain an extensive signal processing circuitry within the package. They give out either analog or digital output depending on the sensor used. Semiconductor-based temperature sensors with analog output are further classified into subgroups namely, voltage output temperature sensor, current output temperature sensor, resistance output temperature sensor, diode-based temperature sensor. The digital output type contains multiple components like temperature sensor, an ADC to convert its analog output to digital, a two-wire digital interface, and a few registers to carry out the operations in IC. These sensors continuously monitor temperature changes and can be accessed at any time. An example of such sensor would be the LM35 series. This series consists of precision based ICSs whose output voltage is directly proportional to the actual temperature in degree Celsius.

These ICs give out precise digital representations of the temperature they are measuring. These sensors don’t contain the analog to digital converter part and are thus simpler compared to other semiconductor sensors. They too have a wider temperature range (-55 C to 125 C) and convert analog temperature into digital form in less than a second. An example for this would be HTU21D.

HTU21D temperature/Humidity sensor. Image taken from source

Temperature range This decides the exact range in which the sensor should be operated. If a sensor has a range from -55 C to 125 C, then it shouldn’t go below or exceed that range as the sensor would end up getting damaged. So by knowing the range, we will know where to install it. A wider range makes the sensor compatible for multiple purposes.

Linearity demonstrates that a unit change in temperature should be equal to a unit change in voltage output across the entire temperature range of the sensor. This is the condition for an ideal sensor but in actual practice, the ideal sensor doesn’t exist. Mostly this property holds its position while the sensor remains in its predefined range.

Response time It is the time taken by a sensor to respond to change in temperature. This depends on a lot of factors like the size of the sensor element and self-heat generating error. A digital sensor will always have a lesser response time than an analog type.

Sensitivity decides how small of a change in temperature can a sensor detect. This property indicates the change in output for a given change in temperature. But the problem is that a more sensitive sensor might be less linear. So a choice has to be made depending on the application.

Stability indicates the ability to maintain a consistent output at a particular temperature throughout the operation. Sensor material plays an important role in deciding this factor. The physical properties of the material have to be taken into account before deploying the sensor. For example, a sensor that is made of a material which has very low melting point might bend or get displaced when exposed to relatively higher temperatures. This will affect the output reading of the sensor.

Accuracy is a very important part to decide as the reliability of the sensor depends highly on it. Accuracy depends on the hardware used in the sensor as well as on other physical parameters like the relative proximity of the sensor to other objects, shielding, grounding etc. To keep the accuracy high, the sensor should be placed in conditions which are well suited. Prolonged exposure to the harsh environment might damage the sensor and change its accuracy.

Durability For temperature sensor to work at an optimal level in its entire duration, the environment in which it is deployed has to be taken into full consideration. There are different types of sensor elements with different properties that are chosen as per the environment. Thermocouple sensor types are robust and don’t get damaged easily. Also there metal encasing has an anti-corrosive metal coating over it. So this type is optimal for a rough environment where other variants might malfunction.

Cost is a key limiting factor when it comes to choosing the type of sensor element. Total sensor cost depends on various parameters like mounting, wiring, and level of signal conditioning required. Also, the user must consider his exact needs and then choose the temperature sensor in order to make it work efficiently.

|

Characteristics |

Thermistors |

RTD | Thermocouples | Semiconductor sensors/Digital Sensors |

Infrared |

|

Temperature Range |

-55 C to +125 C | -200 C to +850 C | -600 C to +2000 C | -50 C to +150 C | -45 C to 85 C |

|

Linearity |

Exponential | Fairly linear | Fairly linear | Best |

Fairly linear |

|

Sensitivity |

High | Low | Medium | Highest | Medium to High |

|

Response time |

Fast | Slow | Fast to slow | Slow |

Fast |

|

Stability |

Low | High | High | Medium |

Medium |

|

Durability |

Poor | Good | Excellent | Excellent |

Good |

|

Self Heating |

Yes | Yes | No | No |

No |

| Cost |

Low |

Low to High |

Moderate to high |

Low to moderate |

Low to moderate |

A wireless temperature sensor is a device which senses the physical degree of heat, records it and sends it to the Gateway which in turn pushes it to the server. It is nothing but a combination of microcontroller, radio frequency (RF) module, a temperature sensing component and other supporting components like resistors, capacitors, crystals etc. The microcontroller is the heart and brain of the product. The necessary programming is done based on the calculations to accurately measure the temperature.It also controls the behavior of the rest of the components. An 8-bit microcontroller is sufficient for this purpose. An example of such microcontroller would be the STM8 series which are cheap, robust and carry a lot of functionalities. RF module is the part which is responsible for its communication with the Gateway. Temperature sensing element can be any one of the above-explained sensors. The user can decide to implement any of these sensors as per the requirement and mounting conditions. The sensor can be powered up with two AA batteries(3V) or a lithium-ion battery.

Monnit, Baseapp, Banner, Jumo, Omega, Phase IV, Web ID Systems, Nimble etc are some of the websites from where you can buy these sensors. These websites provide you with a choice of different powering options. Monnit sells 2 variants of this sensor. Industrial grade sensor that works on 2 AA batteries. The domestic version that is smaller in size and works with a single coin cell battery. They also have different temperature ranges for each of the sensors so that the user can make a choice as per his/her demands. Also, they have given the option to choose the frequency at which the sensor will communicate. The frequencies that they provide are 900 MHz, 868 MHz, 433MHz, and 920MHz.

Before proceeding to buy this sensor, you must ask yourself the following questions.

A lot of companies nowadays sell commercial and industrial wireless temperature sensors. The same company sells different varieties of temperature sensors based on different technologies and have different features like measurable temperature range, accuracy, frequency etc. The buyer must go through all possible options in order to select the best option. Some popular vendors are mentioned below. If you want to buy right now, you can consider these companies.

The links to the websites are mentioned in buy column.

Company |

Features |

Estimated per unit pricing |

Buying Website |

|

Coin cell variant/AA battery variant:

|

Coin cell: $49.00 AA variant: $74.00 Industrial: $149.00 |

BUY |

|

|

Contact Vendor | BUY |

|

|

$213.00 | BUY |

|

|

Contact Vendor | BUY |

|

|

Contact Vendor | BUY |

|

|

With internal Probe - $179 + Subscription charges

With external Probe - $189 + Subscription charges

|

BUY |

|

|

$159.00 | BUY |